From outside, you can hear the excited chatting of students and the sounds of tools in the background. Inside students are diligently exploring the functionality of 3D pens; parents and student aids are not far behind, observing their students’ play and creativity in The MILL Makerspace.

This group of students happened to have visual impairments and came to The MILL on a field trip through Cascade Regional Inclusive Services. Cascade Regional Inclusive Services is an organization related to the Linn Benton Lincoln Educational Services District, that provides a host of services to students with low-incidence disabilities.

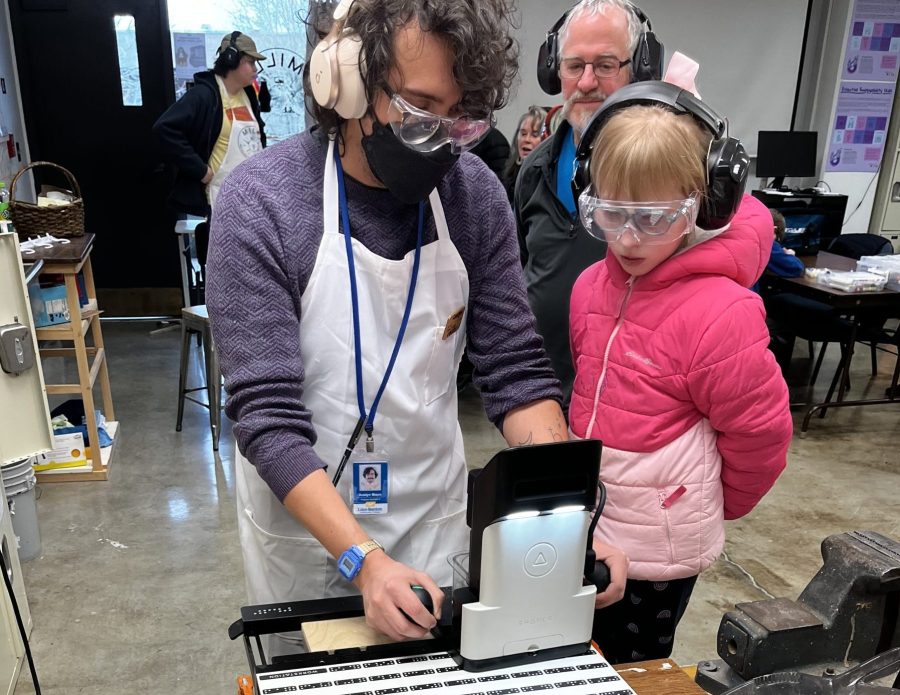

Today the students worked on creating a two-dimensional design and transforming it into a three-dimensional tactile object with the help of technology, specifically the Shaper Origin. A Shaper Origin is a handheld CNC router or a computer numerical controlled router that uses programming and computer vision to correct for human error when routing a design.

It is hard to use a router to engrave plywood. The sharp spinning bit catches the wood and before you know it you are cutting exactly where you don’t want to be cutting. It takes muscle and precision, not to mention numerous custom jigs, to engrave a custom sign. The Shaper Origin’s technology makes custom engraving an easy and approachable experience for all users, leveling the playing field for those just beginning to learn that type of work or for those students who may otherwise not be able to participate in such activities.

As the session in the makerspace reached full swing, students were tasked with creating a simple design, like their name, a star, or a heart with a sharpie inside a 3” circle. Students then scanned their designs using Shaper Trace, sending it to the Shaper Origin’s onboard computer. Once their designs were scanned in, students held on tight to the Shaper and guided the machine as it engraved the outline of their designs with the help of a bright high-definition screen mounted on top of the Shaper and the friendly, knowledgeable MILL staff.

While the technology is helpful, make no mistake, the final product is the result of the student’s work. After they cut their designs out of wood, students were encouraged to make a button using their paper designs. At the end of the day, each student got to take home several projects they themselves made by hand. Demonstrating the design process from ideas to the final product.

“We designed The MILL with accessibility in mind. We made wide alleyways between equipment and keep the floor clear of obstructions,” said MILL Coordinator Forrest Johnson.

The entire space was open to the students to explore and one student even found a new interest in the art of recording while traversing the podcasting equipment in the AV lab.

“It was great to see the students having fun and being engaged as they tried something new, our aim with The MILL is to empower all students to get outside their comfort zone and learn something new,” said Johnson.

Interested in scheduling The MILL for a field trip destination? Email The MILL to get on our calendar.